But how will you know which one will work for your requirement without knowing what a practical board is and the properties of the different particle boards?

Meaning of Particle Board

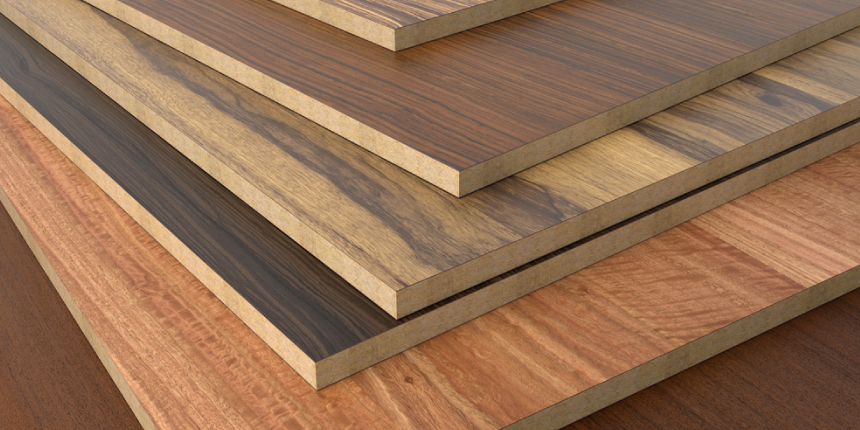

Engineered wood products of a lower density than MDF, particle boards are more popular as low-density fibreboard (LDF). Home interior decorators often refer to them as chipboard.

The wood base particle board material utilised to make these boards comprises sawdust, woodchips, and sawmill shavings glued together with resins. The wood pulp particle board is an eco-friendly product that resists moisture.

Manufacturers of particle boards use plastic laminate, veneer, or printed photo layer to give it a stained and knotted wood finish.

Particle Board Uses

When cost, durability, and aesthetics are primary concerns, the versatile wood particle board is the solution.

Particle boards are available in sheets with varying thicknesses, and you can use them for false ceilings, wall units and panelling. Plywood and MDF particle boards are the most cost-effective because their manufacture involves fewer processes and, thus, low production costs.

These boards work well with machines to make stunning and trendy, flexible furniture with a perfect finish.

Seamless Particle Board Flooring

The transition from ordinary floor to decorative sub-floor surfaces can be inexpensive using particle boards. They are hardwearing and do not dent or scratch easily.

You can use carpets, vinyl, parquet or ceramic tiles to cover the particle board furniture surface. The maintenance cost is also relatively cheap because they are fungus resistant.

Modular Particle Board Furniture

You can create some of the best modular furniture designs with the help of Particle board furniture.

And if you prefer a more DIY approach, then you couldn’t find more affordable material than chipboard.

Particle Board Roof Sheathing

Particle boards work well for the roof, provided it is not the outermost layer.

These boards have excellent sound absorption properties, thus, are superior roof sheathing materials for people living in noisy locations.

The insulation properties of chipboards keep the room warm during winter and cool during summer and hence help lower your electricity bills.

So here’s how you can save a lot of money— use the ASTM type 2-M-W of particle board roof sheathing.

Types of Particle Board

These home interior decoration boards fit well with the latest trends, where interior designers must include everything in a small space.

Wood particle boards are excellent for minimal and elegant furniture. Since these particle board planks are man-made, they have zero structural defects and better screw-holding strength than other wood products. The grading of particle boards depends on their density.

The interior designs requiring materials that help fasten screws better must pick the denser particle boards.

1. Single-Layer Particle Boards

Made of waste wood of uniform size, single-layer particle boards are water resistant but not waterproof.

Thus, they are multipurpose interior decorating materials but perform less as exterior building materials. These boards are dense and flat, and you can layer the top with veneer or plastic lamination, but you cannot paint them.

2. Veneered Particle Board

The Particle boards with sliced, swan or rotary-cut veneers as cross-bands and on their faces are veneered particle boards. There are four types of veneered particle boards that you can choose from as per your interior decorating needs.

The difference is they may be of a solid or tubular core with only one difference one has a general-purpose veneer, and the other has decorative veneer on one or both faces.

Particle board uses are suitable to use for interior decorative purposes in rooms that are humid or have moisture.

3. Laminated Particle Board

The single-layer particle board with a layer of lamination on top is the laminated particle board.

It is versatile for interior decoration because you can choose one in colour to match and blend with the room’s colour scheme. The lamination increases the resilience of the particle board and enhances the aesthetics of your home interior design.

4. Three-Layer Particle Board

Ideal for painting, the three-layer particle board consists of three layers of wood pulp.The top and bottom layers are of small, extremely dense wood chips, and the in-between layers are large wooden shavings.

The outer layer had a lot of resin, giving it a smooth finish.

5. White Particle Board

Superior quality wood or wood chips bond under high pressure to make white particle boards look lavish. These boards are hardwearing and thus suitable for the carcass of kitchen cabinets and wardrobes. White particle boards are easy to cut to size and have a seamless finish that enhances the home interior design.

6. Plain Particle Board

Denser than plywood, plain particle board is suitable for building, and the furniture industry uses them for multiple purposes. These cost-effective building materials are resilient and work well for edging and cutting.

Plain particle boards are best for lightweight and decorative handicraft products, table tops, cupboards, and other minimalistic essentials.

7. Graded-Density Particle Board

You can use the graded-density particle board to create trendy modular kitchen cabinets and furniture to blend with your contemporary home interior design style.

The manufacturers of these practical boards layer a layer of ununiform large wood pieces between two layers of refined wood pulp.

8. Rice Husk Particle Board

The waterproof particle board whose primary raw material is rice husk is the rice husk particle board.

It withstands any temperature and is a cost-effective alternative to Glass Fiber Reinforced Concrete for beautiful exteriors. It’s moldable, so it works well for luxurious interior designs.

9. Aluminium Particle Board

These particle boards comprise aluminium shaving and sawdust and waste glass pieces. Aluminium particle boards don’t function well for structural purposes but are helpful for interior designs such as partitions.

10. Cement-Bonded Particle Board

The bonding agent for wood base particle boards is a chemical resin, but portland and magnesium-based cement do the job for cement-bonded particle boards.

Although it contains wood chips, shavings and sawdust, the major party of the composition comprises cement, and the whole thing combines with a portion of water equal to that of wood products.

These boards work for structural purposes, resistant to moisture, changing climate and bugs. The fire, rot and termite-resistant particle boards make spectacular false ceilings, concrete floors and wall coverings.

Particle board, Plywood or MDF?

So which is the best for home interior design, particle board, plywood or MDF? All three types have their advantages and disadvantages.

Thus to decide on suitable materials, check their applicability and durability in the weather conditions that prevail in your locality.

Take your pick per your home interior decorating needs and climatic conditions.

In Conclusion

With the various types of particle boards available in the market, it can take time to find the right one to serve your home interior requirements.

Please read the article to know what a practical board is, its usability and durability and its types before choosing one that will make your home interior design elegant and affordable.

For more information on particle boards and interior home designs, visit Interior Company.

***Images used are for illustration purposes only. Interior Company does not hold any copyright to the images unless mentioned explicitly.